Model 50-100 shown with optional touch screen.

No moving or rotating internal parts

- Space-saving compact design available for process rates up to 750 lbs/hr.

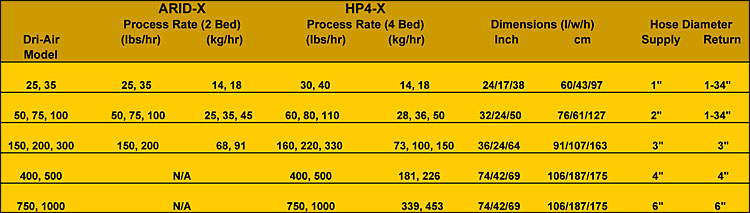

- Models are available in industry-standard 2-bed (ARID-X FM Series) and high-performance 4-bed (HP4-X FM Series)

- Combine with a press/extruder mounted drying hopper for a complete system

- Dryer hoses and casters are included

Energy efficiency:

- Most energy efficient dryer in the market (when compared to compressed air, rotary wheel, vacuum and other dual bed dryers)

- Single blower design for process and regeneration air

- On-demand regeneration; adjusts to ambient conditions, materials and process rates

- Desiccant tower design maximizes heat transfer

- -49ºF to -130ºF dew points; as dry air, not ambient air is used for regeneration or cool down of desiccant towers, slip stream of low dew point air is used

System Features:

Model 150, 200 & 300 shown with ADC control and optional water after-cooler

- Can be used with Hopper Bank Series and multi-hopper systems

- ADC Control is standard and includes:

- -49 F dewpoint monitor

- 7 day timer

- Diagnostic functions

- Dewpoint, heater, and temperature alarm

Optional items include:

- Water after-cooler, plasticizer trap and high temperature hose

- Visual and audible alarms available

- Temperature setback reduces drying temperature when material is dry to prevent overdrying

- Dri-Touch, 7″ touch screen on HP4-X models

Removable panels allow for easy access to internal components