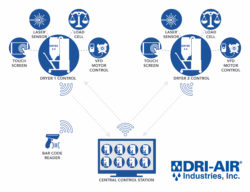

Industry 4.0. Setting the stage for the future of plastics drying, Dri-Air Industries will introduce its new technology, Dri-Air Dryer 4.0, which will be incorporated seamlessly into the rapidly trending Industry 4.0. Dri-Air Dryer 4.0 is designed to work autonomously making changes in operation based on sensors that monitor the changing material throughput. No hands-on equipment operation is required. This dryer will be able to communicate with other equipment in the cell once the protocol is fully developed by Euromap. Each dryer can report to a common station normally located in the maintenance department to monitor their status and any alarms requiring assistance. As dryers are added, they automatically are sensed by the central station and added to the system. Industry 4.0 experts will be available at Booth 971 to assist you in planning your plant’s conversion to Industry 4.0.

Industry 4.0. Setting the stage for the future of plastics drying, Dri-Air Industries will introduce its new technology, Dri-Air Dryer 4.0, which will be incorporated seamlessly into the rapidly trending Industry 4.0. Dri-Air Dryer 4.0 is designed to work autonomously making changes in operation based on sensors that monitor the changing material throughput. No hands-on equipment operation is required. This dryer will be able to communicate with other equipment in the cell once the protocol is fully developed by Euromap. Each dryer can report to a common station normally located in the maintenance department to monitor their status and any alarms requiring assistance. As dryers are added, they automatically are sensed by the central station and added to the system. Industry 4.0 experts will be available at Booth 971 to assist you in planning your plant’s conversion to Industry 4.0.

Building on more than 30 years of drying expertise, Dri-Air Industries will display its leading range of drying and blending equipment at NPE 2018 throughout Booth 971. Small volume, portable dryers are displayed with large volume equipment to provide large and small customers with “one-stop“ shopping.

Small Throughput Dryers. Portable dryers which combine the dryer and hopper on a common stand mounted on casters range from 2 to 350 pounds per hour throughput and are the most common dryers available today.

Hopper Mount Dryers. Gain valuable floor space by mounting the dryer on the feed throat. Available in hopper capacities of 30 to 150 pounds these models are ideal for long runs where cleaning is not a factor.

Dual Hopper Dryers. Our PDII model incorporates 2 hoppers with the dryer for quick material changes ideal for JIT manufacturing. Various sizes of these models will be on display. All of these dryer models are the most efficient dryer available with up to 50% less energy required compared to the wheel style design.

Drying and Blending Systems. To prevent the pickup of moisture while blending dried resins in standard gravimetric blenders, Dri-Air incorporated volumetric feeders into the PDII dual hopper dryer. This system blends the materials only as needed and conveys the mixture to a receiver on the feed throat of the molding machine. There is no moisture pickup, no layering of materials, and no mixture left after completing the job.

Hopper Banks. A variety of our hopper banks will be displayed showing the different amounts and sizes of hoppers that are available on a portable stand. These are ideal for pre-drying resins for JIT processing with manual material handling or they can include one of our central conveying system for automatic operation. Hopper sizes can range from 5 to 300 pound capacity when mounted on a common frame. Larger hoppers are mounted on individual stands that bolt together and include the manifolds, heaters, and loading system piping.

Large Throughput Dryers. We also provide central drying and conveying systems from small to large amounts of machines and throughputs. The system can be supplied from the silos, rail car unloading, conveying to day bins and central drying station, and distributed to individual molding machines. Dri-Air Industries has introduced a series of large dryers with throughputs up to 3000 pounds per hour for PET applications. Using a similar design as our other dryers, these models are much more efficient than any other design on the market. Longevity is enhanced with no moving parts as in the wheel design.

Get your Quote at NPE. Dri-Air Industries will have a complement of personnel ranging from sales, service, and management along with selected agents representing the entire U.S. and export markets. Quotations for specific equipment will be sent to the customer’s attention before the end of each day to enable them to return to the booth to answer any additional questions.

See us in Booth W971 to see the latest in drying technology, to discuss a problem area, or just to say “Hello” to old friends. We look forward to continue to supply your company with our quality products and the opportunity to introduce our products to new accounts.