As taken from Plastics Machinery Magazine article by Bruce Adams September, 2019 Issue page 7

DRI-AIR INDUSTRIES is introducing its new Industry 4.0-compliant SmartTouch Control to

a small group of injection molding customers this month. The new control will gather data from the dryer and seamlessly share it with various pieces of equipment, such as the injection molding machine.

“The new control is based on an open platform and will consist of a PLC with a thermocouple monitoring system,” Dri-Air Industries President Jason Sears said. “We want to stay on the leading edge of technology for customers who want to gather data and monitor their processes.” The open platform will allow users to add new sensors, communications devices or protocols that may become available in the future, he said.

Initially, four injection molding companies will use the SmartTouch Control and provide feedback to Dri-Air. Dri-Air plans to offer the new control to all customers later this year. It will be compatible with all Dri-Air dryers.

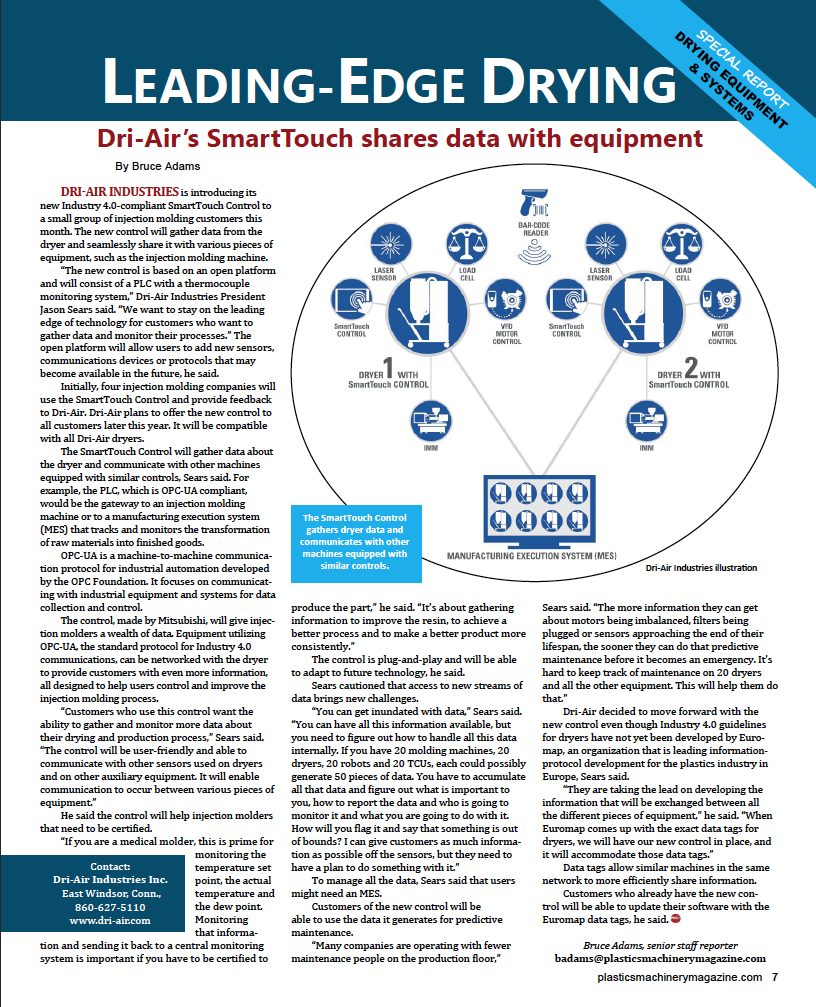

The SmartTouch Control will gather data about the dryer and communicate with other machines equipped with similar controls, Sears said. For example, the PLC, which is OPC-UA compliant, would be the gateway to an injection molding machine or to a manufacturing execution system (MES) that tracks and monitors the transformation of raw materials into finished goods.

OPC-UA is a machine-to-machine communication protocol for industrial automation developed by the OPC Foundation. It focuses on communicating with industrial equipment and systems for data collection and control.

The control, made by Mitsubishi, will give injection molders a wealth of data. Equipment utilizing OPC-UA, the standard protocol for Industry 4.0 communications, can be networked with the dryer to provide customers with even more information, all designed to help users control and improve the injection molding process. “Customers who use this control want the ability to gather and monitor more data about their drying and production process,” Sears said.

“The control will be user-friendly and able to communicate with other sensors used on dryers and on other auxiliary equipment. It will enable communication to occur between various pieces of equipment.” He said the control will help injection molders that need to be certified. “If you are a medical molder, this is prime for monitoring the temperature set point, the actual temperature and the dew point.

Monitoring that information and sending it back to a central monitoring system is important if you have to be certified to produce the part,” he said. “It’s about gathering information to improve the resin, to achieve a better process and to make a better product more consistently.”

The control is plug-and-play and will be able to adapt to future technology, he said. Sears cautioned that access to new streams of data brings new challenges. “You can get inundated with data,” Sears said. “You can have all this information available, but you need to figure out how to handle all this data internally. If you have 20 molding machines, 20 dryers, 20 robots and 20 TCUs, each could possibly generate 50 pieces of data. You have to accumulate all that data and figure out what is important to you, how to report the data and who is going to monitor it and what you are going to do with it. How will you flag it and say that something is out of bounds? I can give customers as much information as possible off the sensors, but they need to have a plan to do something with it.”

To manage all the data, Sears said that users might need an MES. Customers of the new control will be able to use the data it generates for predictive maintenance. “Many companies are operating with fewer maintenance people on the production floor,” Sears said. “The more information they can get about motors being imbalanced, filters being plugged or sensors approaching the end of their lifespan, the sooner they can do that predictive maintenance before it becomes an emergency. It’s hard to keep track of maintenance on 20 dryers and all the other equipment. This will help them do that.”

Dri-Air decided to move forward with the new control even though Industry 4.0 guidelines for dryers have not yet been developed by Euromap, an organization that is leading information protocol development for the plastics industry in Europe, Sears said. “They are taking the lead on developing the information that will be exchanged between all the different pieces of equipment,” he said. “When Euromap comes up with the exact data tags for dryers, we will have our new control in place, and it will accommodate those data tags.”

Data tags allow similar machines in the same network to more efficiently share information. Customers who already have the new control will be able to update their software with the Euromap data tags, he said.

by Bruce Adams, senior staff reporter for PMM Magazine

badams@plasticsmachinerymagazine.com