AHEAD OF INDUSTRY 4.0 AND MOLDING 4.0, WE WELCOME OUR NEWEST INNOVATION, THE DRI-AIR DRYER 4.0

The buzz in the resin processing industry these days is Industry 4.0, a trend where many technological and digital advances that began with consumer products now are being introduced to the Factory of the Future. While developments such as Bluetooth wireless technologies and Internet Connectivity have been available in consumer products for more than a decade, their integration to the production facilities that manufacture advanced products has been much more recent.

Taking advantage of many current scientific developments, Dri-Air is developing a new series of dryers known as Dri-Air Dryer 4.0. These dryers utilize internet capabilities to create dryers that solve many issues which have been common to plastics processing for years. Dri-Air Dryer 4.0 adjusts to conditions and changes in the operation autonomously, gathering information and adapting on its own.

AUTONOMOUS OPERATION

Have you been troubled by shutdowns caused by dirty filters that reduce air flow in your dryer? Dri-Air Dryer 4.0 incorporates cyclonic removal of fines coupled with a visible collector of waste that notifies your maintenance team when it is full, virtually eliminating filtration cartridges.

Are you able to compare cycle times among your machines to assure that you have the best cycles for all of your equipment? Using Dri-Air Dryer 4.0 wireless technology, you can compare cycle times among dryers, molding machines and robots to determine the optimum cycle for your equipment.

Does your maintenance team have to rewire the rotation on blowers each time they move a dryer? Dri-Air Dryer 4.0 automatically senses and changes the rotation as needed.

Do you use annoying alarms to assure that relays and heaters in dryers are functioning? Solid state relays in Dri-Air Dryer 4.0 monitor the heaters and drastically reduce the need for any alarms.

Are you utilizing return heat exchangers to manage your dryers when process temperature exceeds 250 degrees? Dri-Air Dryer 4.0 senses and controls the air flow, temperature and hopper content, resulting in low return temperature that eliminates heat exchangers.

Do your operators need to commit extra time to adjust material levels in dryer hoppers? Dri-Air Dryer 4.0 automatically controls levels by reading actual throughput of plastic and drying times. Laser sensors and load cells calculate the amount of material in the hopper and monitors the throughput of resin for optimum operation.

Have you had product ruined by spending excess time above the dryer feed throat, resulting in excess moisture, which affects cavity pressure and part quality? Dri-Air Dryer 4.0 adjusts fill time automatically.

Have your operators had to commit time watching process temperature so they can adjust it when optimum temperature is exceeded? Dri-Air Dryer 4.0 adapts air flow and process temperature with a state of sleep mode by idling the regeneration cycle, reducing operating energy by 80%.

Do your dryer motors ever burn out without notice? Dri-Air Dryer 4.0’s state-of-the-art motor control monitors performance and longevity of the motor, reporting its information to the main control package and to other connected data collection packages.

SUPPORTING YOUR TEAM

Virtually all manufacturers report a reduction in the availability of maintenance personnel as well as a lack of trouble shooting skills among maintenance staff. Although Dri-Air dryers have been known for minimal maintenance over the years, there have been occasional situations where significant amounts of rejects were produced before a dryer problem was detected. Dri-Air Dryer 4.0 makes this possibility virtually disappear.

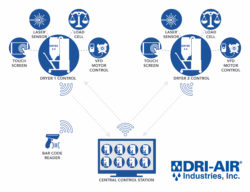

For customers with multiple Dri-Air Dryer 4.0s, a central dryer control is installed in the Maintenance Office or other convenient location for service response. Each dryer’s operating parameters and other important data are displayed on the main screen. When a dryer needs servicing, the dryer icon flashes showing what needs to be done, directions for service and the parts required. As a new Dri-Air 4.0 dryer is installed, it is automatically added to the group display, compares spare parts required and specifies new spare parts to be ordered. An inventory package to track and store the spare parts is under development.

To enable servicing by Maintenance Staff not highly trained in dryer operation, Dri-Air Dryer 4.0 is designed for ease of care through modular construction. Modules include power supply, input module, output module, tower module and air control module. These modules all used connectors, couplings or other fastening devices to quickly replace several individual components. The Dri-Air 4.0 controls identify which module needs replacing, instruct how to install it, and whether it is in stock. The modules can then be serviced by the customer or sent to Dri-Air for repair.

To contribute to the customer’s ability to manage a plant with utmost efficiency, Dri-Air 4.0 dryers are capable of communicating with other devices through Ethernet or other protocols.

These Dri-Air Dryer 4.0 conveniences also apply to central drying systems, including temperature control of hoppers and large screen monitoring.

To learn more, visit Dri-Air at NPE Booth #W971, May 7-12, 2018. Or contact us at Dri-Air Industries, 16 Thompson Road, East Windsor CT 06088. www.dri-air.com. (860) 627-5110