Diffuser basket is constructed of spun stainless steel with a slip coupling for easy removal.

Laser-cut access doors provide a smooth, tight fit and eliminates troublesome gaskets.

Uniform drying coupled with easy accessibility for cleaning are key to proper hopper design.

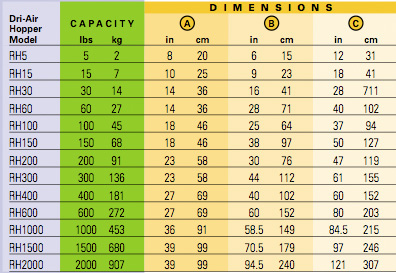

- Standard sizes range from 5 to 2000 lbs (2 to 907 kg); based on 35 lbs/ft3*

- Unique diffuser basket dries resin down to the slide gate and allows for drying less than full hoppers.

- Full length site glass is standard on Models RH60 and larger.

- Insulated side walls eliminate heat loss and conserve energy.

Note: RH5, RH15, and RH30 do not have access doors. *Larger hoppers available, consult factory.

System Features:

- Exclusive basket design assures dried material down to the slide gate – no slugs of undried material

- No tools required for hopper cover

- Internal ring on hopper cover prevents damage to hopper loaders

- Easy-close slide gate on RH400 thru RH2000 hoppers

- Insulated side walls eliminate heat loss and conserve energy

Adjustable fill sensor option ties into hopper loader to accommodate varying process rates for maximum flexibility.